Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

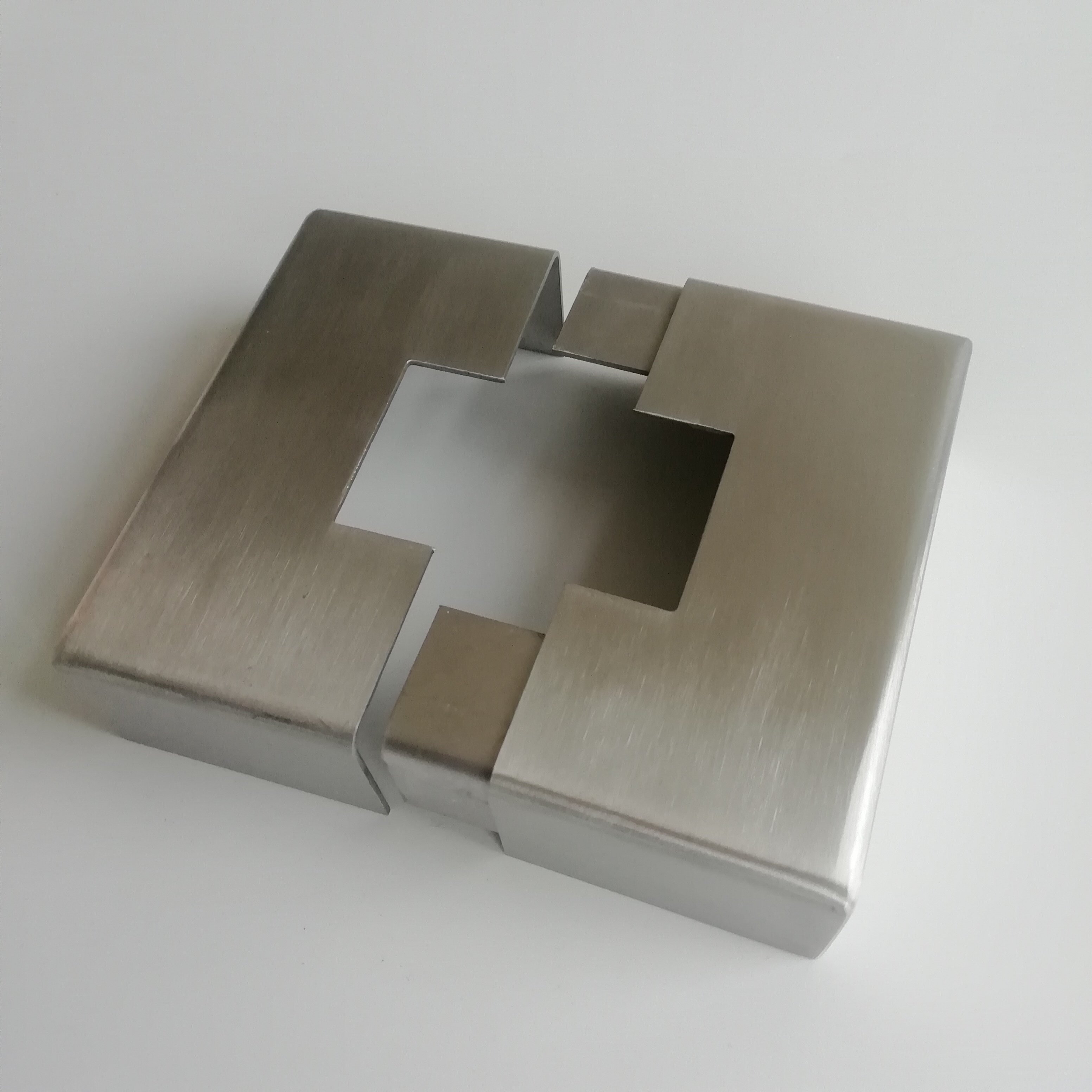

Quality Assurance and Efficiency: The Standards of China Sheet Metal Stamping Parts Factory

As a leading China sheet metal stamping parts factory, we prioritize quality assurance and efficiency in our manufacturing processes. In this blog post, we will delve into the standards we uphold to ensure the highest quality and efficiency in producing sheet metal stamping parts. From material selection to production techniques, we strive to meet and exceed customer expectations while maintaining a streamlined and efficient operation.

Material Selection:

At our China sheet metal stamping parts factory, we understand that the quality of the end product starts with the materials used. We carefully select high-grade metals, such as stainless steel, aluminum, and copper, known for their strength, durability, and corrosion resistance. By using superior materials, we ensure that our stamping parts can withstand various environmental conditions and deliver long-lasting performance.

Advanced Manufacturing Techniques:

Efficiency is a key aspect of our manufacturing process. We employ advanced techniques and machinery to streamline production and minimize waste. Computer Numerical Control (CNC) machines and automated systems enable precise and consistent stamping, reducing errors and increasing efficiency. Our skilled technicians monitor the production process closely, ensuring that each sheet metal stamping part meets the required specifications.

Quality Control Measures:

Quality assurance is at the core of our operations. We have implemented stringent quality control measures to guarantee the reliability and functionality of our sheet metal stamping parts. Throughout the manufacturing process, we conduct regular inspections and tests to identify any defects or deviations. Our quality control team meticulously checks dimensions, tolerances, surface finishes, and overall product integrity. By adhering to these rigorous standards, we deliver products that meet or exceed industry benchmarks.

Continuous Improvement:

As a China sheet metal stamping parts factory, we are committed to continuous improvement. We actively seek feedback from our customers and incorporate their suggestions into our processes. By staying updated with the latest industry trends and technological advancements, we continuously refine our manufacturing techniques to enhance quality and efficiency. Our goal is to provide our customers with the best possible products and services.

Environmental Responsibility:

In addition to quality and efficiency, we also prioritize environmental responsibility. Our China sheet metal stamping parts factory adheres to strict environmental regulations and promotes sustainable practices. We minimize waste generation through efficient material utilization and recycling programs. By implementing energy-saving measures and reducing our carbon footprint, we contribute to a greener and more sustainable future.

Conclusion:

At our China sheet metal stamping parts factory, quality assurance and efficiency are the cornerstones of our operations. Through meticulous material selection, advanced manufacturing techniques, and rigorous quality control measures, we ensure that our products meet the highest standards. By continuously improving our processes and embracing environmental responsibility, we strive to exceed customer expectations while minimizing our impact on the environment. When you choose sheet metal stamping parts from our factory, you can trust in the quality, efficiency, and reliability of our products.