Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Metal Fabrication

Metal Fabrication

(5)Stamping Part

Stamping parts are formed by applying external force to plates, strips, pipes and profiles by presses and molds to cause plastic deformation or separation to obtain workpieces (stamping parts) of required shape and size. Stamping and forging belong to plastic processing (or pressure processing) and are collectively called forging. The blanks for stamping are mainly hot-rolled and cold-rolled steel sheets and strips.

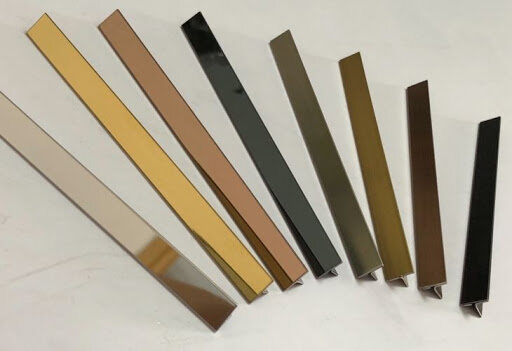

Stainless Steel U Channel Profile

Decorative strips come in a wide range of designs and are frequently utilized. They are frequently used for interior and other décor, real estate development, construction projects, etc. It offers a variety of distinctive qualities, including light weight, lovely surface and line work, ease of installation, and upkeep.

Coil Tube

A hollow, long round steel, stainless steel coil tube finds extensive usage in the chemical, pharmaceutical, food, light industrial, heat exchanger, and mechanical structural parts industries. Additionally, because the weight is smaller when the bending and torsion strengths are equal, it is frequently employed in the production of mechanical parts and engineering structures.

Laser Cutting Part

A wide range of items require the use of metal fabrication, which involves a combination of techniques like cutting, bending, and stamping. Runtian has tools and machinery that can be thoroughly processed.

Bending Part

process known as "bending parts." Metal materials are fundamentally deformed through an elastic-plastic reaction when bent. The workpiece will exhibit directional elastic recovery deformation after unloading, often known as springback. The precision of the workpiece is affected by springback, which is a crucial technology to take into account when bending.