Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

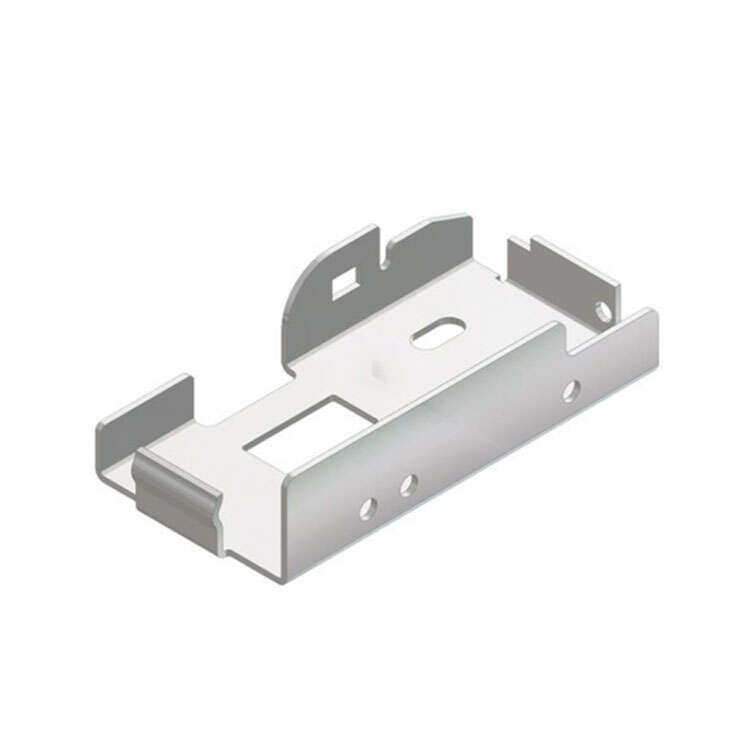

Bending Part

process known as "bending parts." Metal materials are fundamentally deformed through an elastic-plastic reaction when bent. The workpiece will exhibit directional elastic recovery deformation after unloading, often known as springback. The precision of the workpiece is affected by springback, which is a crucial technology to take into account when bending.

Bending Part

Bending parts refer to a stamping process of plastic forming that bends metal materials into a certain angle, curvature and shape. The bending of metal materials is essentially an elastic-plastic deformation process. After unloading, the workpiece will produce directional elastic recovery deformation, which is called springback. Springback affects the accuracy of the workpiece and is a key technology that must be considered in the bending process.

The Standard Specification of Bending Part

|

Material |

Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, Nylon, etc. |

|

Processing |

CNC Turning, Milling, drilling, auto lathe, tapping, bushing, surface treatment, etc. |

|

Surface Treatment |

Polishing, general/hard/color oxidation, surface chamfering, tempering, Sandblasting, Metal Plating, Polishing, Painting, Powder coating, Brushing, Silk-screen, Laser Engraving etc. |

|

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

|

Logo |

Silk print, Laser marking |

|

Size |

Accept custom size. |

|

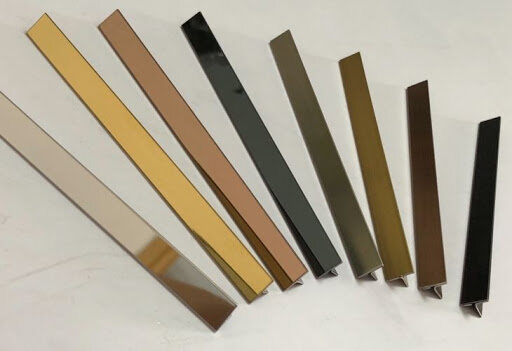

Color |

White, black, silver, red, grey, Pantone and RAL, etc |

|

Drawing format |

DWG, DXF, STEP, IGS, 3Ds, STL, SKP, Al, PDF, JPG, Draft. |

|

Sample lead time |

No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

The manufacturability of Bending Part

1. When the plate is bent, if the fillet of the bend is too small, cracks will easily occur on the outer surface. If the fillet of the bend is too large, the accuracy of the bent part cannot be guaranteed due to the impact of springback.

2. The length of the bent edge should not be too small, otherwise it is not easy to get parts with accurate shape.

3. The bending line should not be located at the part where the width of the part deforms to avoid tearing. If it must be bent at a sudden change in width, the process hole or process groove should be punched in advance.

4. When the blank with holes is bent, if the holes and grooves are located near the bend, the holes will be deformed when bent. In order to avoid such defects, the pores must be distributed outside the deformation zone.

5. For symmetrical bending parts, the left and right bending radii should be consistent, and the force balance during the bending process should be ensured to prevent sliding.

6. When marking the relevant dimensions of the bending parts, the processing technology should be considered, first punching and then bending, the accuracy of the dimension L is easy to guarantee, and it is convenient for processing.